One of the most demanded areas for today is a monolithic construction, used to build a variety of structures. The process of such construction involves the creation of structural elements using a mixture that consists of concrete, as well as formwork. Formwork itself serves as a form for pouring concrete. Thus, the construction of monolithic buildings is impossible without the use of formwork, adding rigidity and stability to structures.

Immense formwork from a very light material – expanded polystyrene – became very popular during the erection of monolithic structures. Such formwork includes panels made of polystyrene, which are connected by special bridges. They have gained great popularity due to their small weight and ease of installation.

When choosing materials for interior and exterior decoration, you should also pay attention to their combustibility, polystyrene foam, in turn, can be burned well. Typically, for such jobs, sheets of gypsum board are used that glue on top of polystyrene. After this, the facade of the house is plastered or covered with various facing materials.

In monolithic construction, special demountable formwork is also used. For example, they are used to build office buildings or civilian high-rise buildings. In this case, the structure can consist of an external wall with a warm facade or a monolithic with internal insulation. These options are used, respectively, for large or small amounts of construction.

Despite the fact that today the construction market offers a lot of proposals for various services, but not every company undertakes the construction of monolithic buildings and few will be able to perform such work in a quality and in a short time. This is due to the fact that such a construction is an innovation in this area and requires certain knowledge and techniques of execution. One of the professional companies is BC SOLID. Experienced engineers with knowledge will be able to complete the whole complex of building monolithic buildings and without problems will give a long-term guarantee for their work.

Month: August 2018

Scope of use of metal structures

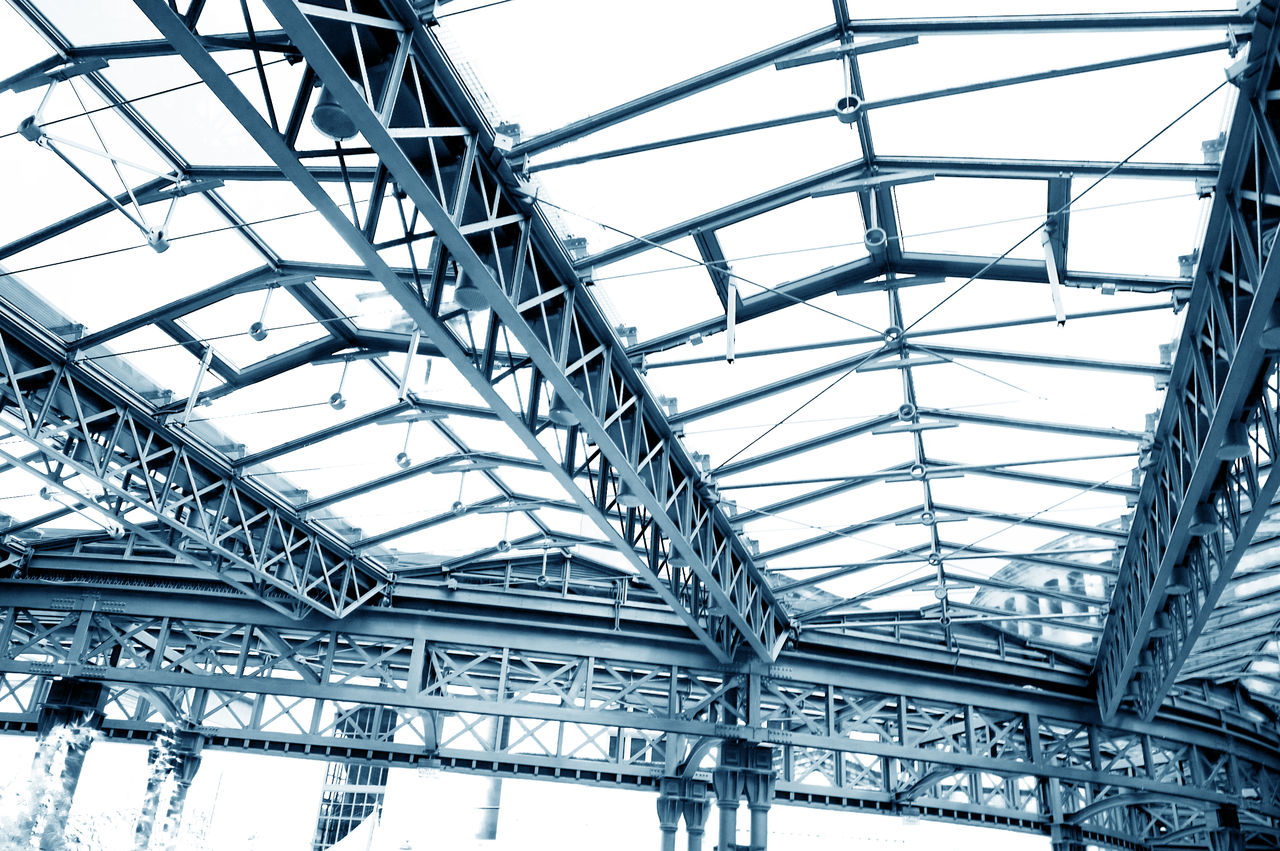

Metal structures are the backbone of buildings and structures of various types and complexity, and such a process as fabrication of metal structures is rather painstaking, as a result of which a unique and reliable kit should be obtained.

The scope of use of metal structures is very wide, without it there is neither agriculture, nor construction, nor engineering and metallurgy. Even the advertising industry can not do without the use of metal structures.

The specificity of metal products is such that they can be divided into two types: light elements and more solid designs.

As for marketing purposes, in this case more often light metal structures are used, since they are easy to assemble, install and disassemble. For example, they are used for billboards or various signage. In this case, the weight of the installation plays a big role, primarily because of the safety for people. At the same time, the manufacture of metal structures of this type will not be a big problem. Light elements of metal structures have a relatively low cost, high speed installation of the complex, as well as small costs in the case of the transfer of structures or their transportation to another location.

If we talk about more fundamental metal structures, they are widely used in civil and industrial facilities. All plants and factories were built using metal structures of varying complexity, they are a guarantee of the durability of the entire complex. The same applies to civil engineering, where the strength of structures is of particular importance and the safety requirements are maximum.

Thus, if you need to make metal structures, it’s best to turn to a professional and experienced company, since it is difficult to overestimate the significance of these structures for any type of construction. Such a company is BC SOLID. A team of experienced engineers will help you in this matter in the shortest time, and you will be satisfied with the result.

Construction of frame hangars, their advantages and disadvantages

To date, in the construction of hangars, there is competition between metal frameworks and arched frameless structures. In any case, the construction of hangars of any kind requires certain skills and each of them has its pros and cons.

Let’s consider in more detail the main advantages and disadvantages of frame hangars. The biggest plus is that such hangars can be built in any shape and practically without any restrictions. However, it is necessary to take into account the fact that over time, corrosion of the metal will start in places where moisture accumulates (at the junction of the sheet and the frame). Therefore, at any time it will be necessary to carry out partial repairs, and this is quite problematic, since the frame itself is a carrier element and it will be difficult to replace any part of it.

In the process of erecting frame hangars, special sandwich panels are used to construct fencing structures. This solution can not be called the best, since with frequent surface treatment of structures the joints of the panels become less sealed, which in turn leads to the development of the fungus and worsens their thermal insulation. Such designs have a weak impact resistance, which subsequently also affects the stability of the entire structure

To that already construction of carcass hangars, namely the way of installation, leads to a significant rise in price of the structure. In this case, a special mineral wool insulation is additionally inserted into the sandwich profiles, then a protective membrane is put on top, and then the entire structure is covered with an additional cladding.

This way of building frame hangars has a number of disadvantages:

– a large mass of the hangar, in this connection a solid foundation is required;

– The total cost of construction will also depend on the costs of transporting large panels;

– The cost of construction also increases the use of special coatings for protection from ultraviolet and corrosion;

– thanks to the prefabricated type, wireframe hangars can be easily dismantled, but the costs of such a procedure are often unjustified, as they reach the cost of a new hangar.

Nevertheless, wireframe hangars continue to be popular, as they are simple in design, and are quickly assembled and disassembled.

In such a question as the construction of frame hangars you will help “BC SOLID”. A team of professionals will execute for you a project of any complexity.