One of the most demanded areas for today is a monolithic construction, used to build a variety of structures. The process of such construction involves the creation of structural elements using a mixture that consists of concrete, as well as formwork. Formwork itself serves as a form for pouring concrete. Thus, the construction of monolithic buildings is impossible without the use of formwork, adding rigidity and stability to structures.

Immense formwork from a very light material – expanded polystyrene – became very popular during the erection of monolithic structures. Such formwork includes panels made of polystyrene, which are connected by special bridges. They have gained great popularity due to their small weight and ease of installation.

When choosing materials for interior and exterior decoration, you should also pay attention to their combustibility, polystyrene foam, in turn, can be burned well. Typically, for such jobs, sheets of gypsum board are used that glue on top of polystyrene. After this, the facade of the house is plastered or covered with various facing materials.

In monolithic construction, special demountable formwork is also used. For example, they are used to build office buildings or civilian high-rise buildings. In this case, the structure can consist of an external wall with a warm facade or a monolithic with internal insulation. These options are used, respectively, for large or small amounts of construction.

Despite the fact that today the construction market offers a lot of proposals for various services, but not every company undertakes the construction of monolithic buildings and few will be able to perform such work in a quality and in a short time. This is due to the fact that such a construction is an innovation in this area and requires certain knowledge and techniques of execution. One of the professional companies is BC SOLID. Experienced engineers with knowledge will be able to complete the whole complex of building monolithic buildings and without problems will give a long-term guarantee for their work.

Category: Blog

Scope of use of metal structures

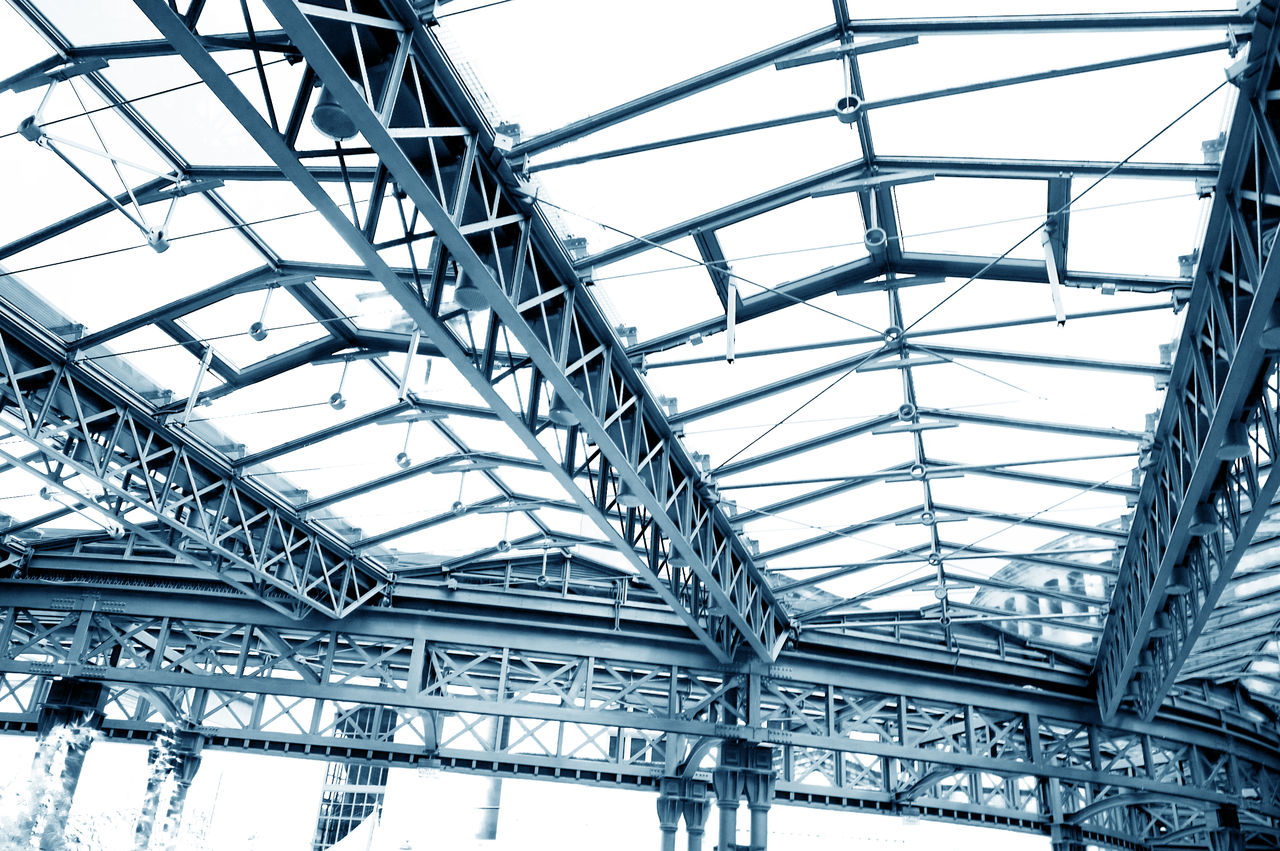

Metal structures are the backbone of buildings and structures of various types and complexity, and such a process as fabrication of metal structures is rather painstaking, as a result of which a unique and reliable kit should be obtained.

The scope of use of metal structures is very wide, without it there is neither agriculture, nor construction, nor engineering and metallurgy. Even the advertising industry can not do without the use of metal structures.

The specificity of metal products is such that they can be divided into two types: light elements and more solid designs.

As for marketing purposes, in this case more often light metal structures are used, since they are easy to assemble, install and disassemble. For example, they are used for billboards or various signage. In this case, the weight of the installation plays a big role, primarily because of the safety for people. At the same time, the manufacture of metal structures of this type will not be a big problem. Light elements of metal structures have a relatively low cost, high speed installation of the complex, as well as small costs in the case of the transfer of structures or their transportation to another location.

If we talk about more fundamental metal structures, they are widely used in civil and industrial facilities. All plants and factories were built using metal structures of varying complexity, they are a guarantee of the durability of the entire complex. The same applies to civil engineering, where the strength of structures is of particular importance and the safety requirements are maximum.

Thus, if you need to make metal structures, it’s best to turn to a professional and experienced company, since it is difficult to overestimate the significance of these structures for any type of construction. Such a company is BC SOLID. A team of experienced engineers will help you in this matter in the shortest time, and you will be satisfied with the result.

Construction of frame hangars, their advantages and disadvantages

To date, in the construction of hangars, there is competition between metal frameworks and arched frameless structures. In any case, the construction of hangars of any kind requires certain skills and each of them has its pros and cons.

Let’s consider in more detail the main advantages and disadvantages of frame hangars. The biggest plus is that such hangars can be built in any shape and practically without any restrictions. However, it is necessary to take into account the fact that over time, corrosion of the metal will start in places where moisture accumulates (at the junction of the sheet and the frame). Therefore, at any time it will be necessary to carry out partial repairs, and this is quite problematic, since the frame itself is a carrier element and it will be difficult to replace any part of it.

In the process of erecting frame hangars, special sandwich panels are used to construct fencing structures. This solution can not be called the best, since with frequent surface treatment of structures the joints of the panels become less sealed, which in turn leads to the development of the fungus and worsens their thermal insulation. Such designs have a weak impact resistance, which subsequently also affects the stability of the entire structure

To that already construction of carcass hangars, namely the way of installation, leads to a significant rise in price of the structure. In this case, a special mineral wool insulation is additionally inserted into the sandwich profiles, then a protective membrane is put on top, and then the entire structure is covered with an additional cladding.

This way of building frame hangars has a number of disadvantages:

– a large mass of the hangar, in this connection a solid foundation is required;

– The total cost of construction will also depend on the costs of transporting large panels;

– The cost of construction also increases the use of special coatings for protection from ultraviolet and corrosion;

– thanks to the prefabricated type, wireframe hangars can be easily dismantled, but the costs of such a procedure are often unjustified, as they reach the cost of a new hangar.

Nevertheless, wireframe hangars continue to be popular, as they are simple in design, and are quickly assembled and disassembled.

In such a question as the construction of frame hangars you will help “BC SOLID”. A team of professionals will execute for you a project of any complexity.

Industrial building of monolithic buildings

The technology of monolithic construction of industrial buildings allows the construction of large buildings in a short period of time, which differ in strength and reliability. This type of construction is optimal for storey buildings of various shapes.

The process of building monolithic buildings can be divided into such basic stages:

1. Preparation of land. Analysis and compaction of soil.

2. Complex of foundation works.

3. Installation of formwork.

4. Formation of the reinforcing cage of the building.

5. Pouring concrete and forming a monolith.

When building monolithic buildings, the main role is played by the quality of building materials and mixtures. If you use substandard components, concrete will be of poor quality and will soon begin to crumble. BC “SOLID” uses in its work only quality, certified materials.

The main advantages of monolithic construction include:

1. High construction speed.

2. No restrictions in the configuration of buildings.

3. Absence of seams and joints.

4. Longevity of such buildings.

5. High energy efficiency of monolithic buildings.

Qualified employees of the company “SOLID” professionally perform all design and construction work on the industrial construction of monolithic buildings. Certainly, monolithic buildings are considered to be one of the most solid and reliable buildings. Trust construction professionals and the building will serve you for many years. For more specific information, please contact us in any convenient way for you.

Modern materials and construction technologies allow carrying out work at any time of year, regardless of weather and temperature conditions. BC “SOLID” always takes into account all the wishes of customers, performs all the work within the agreed time.

Industrial construction of logistics complexes

With the development of industry and access to new markets, there is a need for the construction of such industrial real estate objects as logistics complexes. Such buildings must meet certain requirements:

1. Logistic complexes should have a large and comfortable adjoining zone equipped for the entrance of transport.

2. The premise should be planned in view of installation of the equipment for high throughput of a logistical complex.

3. A competent internal layout of the complex’s premises should ensure convenient storage and movement of goods inside buildings.

4. When planning the complex, it is necessary to take into account the need to install conveyor belts for the competent movement of goods along the complex.

Modern prefabricated buildings meet all requirements. The undeniable advantage of such buildings is that the construction can take place at any time of the year, regardless of the weather conditions. Unfavorable weather does not affect the technical characteristics of the building.

The development of each logistics complex takes place taking into account all the wishes of the customer. How are construction and installation works going?

1. The customer discusses all the parameters of the future building. A building project is being created.

2. A team of specialists travels to the construction site, conducts soil analysis, prepares a site for construction.

3. The foundation of the future building is built, prefabricated or monolithic. All necessary foundation work is carried out.

4. The frame of the building is being constructed, in accordance with the approved project.

5. Next, walls, windows and other enclosing structures are erected.

6. The floor is equipped.

7. The facade works are produced.

8. The roof is covered with roofing materials.

9. Communication and engineering systems are connected.

10. The necessary equipment is installed to operate the logistics complex.

BC “SOLID” carries out all works connected with the construction of logistics complexes. We are responsibly approaching our work, we carry out construction in a high-quality and fast manner.

Turnkey construction of facades

Appearance plays an important role for the building of any destination. If we talk about shopping centers or business buildings, people first of all pay attention to the facade, and only then on signs and inscriptions. If we are talking about production and storage facilities, then people are much nicer and psychologically comfortable to work in beautiful and colored rooms.

The company BC “SOLID” carries out the construction of any facades on a turn-key basis. A variety of modern materials allow not only to improve the appearance of the building, but at the same time to insulate it and improve the insulation of the premises.

Facade coatings should not only improve the appearance of the building, but also reliably protect it from corrosion and negative influence of the external environment. Another feature of facade materials is that they must be resistant to temperature changes and not deformed at high or low temperature.

Sandwich panels have proved to be a great material for the decoration of building facades. Such panels are practically insensitive to various temperature changes, they do not lose tightness on joints neither in heat, nor in cold. In addition, sandwich panels act as an excellent insulant and noise isolator. A variety of colors and external texture of the panels allow the implementation of a wide variety of design ideas.

Advantages of using sandwich panels for building facades:

1. Simple and quick installation of panels at any time of year, regardless of weather conditions.

2. Easy maintenance of the facade of the building.

3. The plates reliably connect with each other, which additionally protects the building from external factors.

4. The slabs are very resistant to moisture, perfectly protect buildings even in very wet climates.

5. The ventilated zone, which is formed in the process of creating the facade, allows all excess moisture to leave unhindered without condensation on the building.

Modern materials and construction technologies offer you many opportunities. Specialists of BC “SOLID” professionally and “turnkey” will realize all your ideas in life.

Industrial construction of factories

The construction of industrial premises requires a particularly responsible approach. Typically, the requirements for industrial factory buildings are much higher than for simple hangars or warehouses. Technical characteristics of the factory premises should be at a high level.

Modern factories are increasingly located in prefabricated buildings. Projects for such premises are developed taking into account all loads, both external and internal, connected with the plant’s operation.

The building in which the plant can be located must have the following mandatory characteristics:

1. Be reliable and secure.

2. To withstand loads and vibrations from working heavy machinery and movement of vehicles through the plant.

3. Be equipped with a good ventilation system.

4. Have enough windows to penetrate the daylight into the shops.

5. Materials from which the construction of the workshop is made should not cause allergies and be completely safe for people.

When designing factory premises, special attention is paid to ventilation systems and other engineering systems and communications. Conditions are created for the most comfortable and efficient operation of the plant. All factory premises should be convenient for the movement of workers and equipment in the shops. Of course, the design of factory premises takes into account the direction and features of a particular production. Based on operational requirements, an adapted factory plant design is created.

The use of modern building technology based on metal frame allows you to build industrial buildings at any time of the year for a very short time. On the strength of such a structure is not inferior to more capital buildings, but construction time and financial investments are much less. If the production process allows the use of such buildings, prefabricated workshops are the best option.

BC “SOLID” has a wide experience in the construction of various industrial and industrial premises. Qualified employees are responsible for the work. We use only high-quality building materials and mixtures. We carry out all construction work in a qualitative and timely manner. BC “SOLID” – a reliable partner that will not let you down!

Industrial construction of granaries

The construction of granaries is a very important stage in the development of agribusiness, on which the company’s profit will largely depend. Today, business is developing very rapidly, new markets are opening up for the sale of grain. There is a need for the construction of new, modern grain storage facilities, in which the harvest will be well preserved and not be spoiled prematurely. After all, a spoiled crop is irreparable damage to the agrarian. Therefore, the construction of granaries should be trusted only by professionals.

Granaries belong to narrow-profile objects. Such buildings are difficult to use for anything other than their main purpose. Therefore, in the construction of grain storage facilities, we are guided precisely by the operational features and requirements put forward to a particular premise.

The project of each granary built by us was developed for each customer individually, taking into account all the features. At the heart of each storage is a standard project, in which we make changes in accordance with the wishes of the customer. Particular attention is paid to the ventilation system, thermal insulation and air humidity control system. The room should be as functional as possible and comfortable for staff.

Advantages of our granaries:

1. Maximum functionality of the room.

2. Minimal terms of construction.

3. Affordable price for construction.

4. We use only high-quality materials for construction.

5. Our repositories are safe and reliable.

6. High resistance of modern building materials to the negative impact of the environment.

BC “SOLID” carries out a full cycle of construction of granaries. Having ordered construction from us, you can be sure that we will finish the work within the agreed time, we will do everything quickly and efficiently.

Foundation works

The foundation is the foundation of any building. Everyone knows that without a sound and sound foundation it is impossible to build a reliable building, especially when it comes to large areas. Only correctly performed calculations and professionally executed foundation works can guarantee the safety and reliability of the building.

The technology of foundation construction includes such stages as:

1. Analysis and geological evaluation of the soil.

2. Preparation of the foundation for the foundation.

3. Preparing the soil, which includes compaction of soil in the required places.

4. Reinforcement of a concrete structure.

5. Installation of foundation formwork.

6. Assembling or concreting the foundation, depending on the type of foundation.

7. Waterproofing the finished foundation.

Only professional and qualitative soil analysis can determine the bearing capacity of a particular land plot. Without this analysis and a complex of works with the land, the future building risks cracks due to unstable soil.

In order for the load-bearing capacity of the foundation to correspond to the calculations, it is necessary to use only high-quality building mixtures and materials, strictly observe the foundation construction technology.

In general, the foundations are divided into:

• monolithic foundations;

• prefabricated or banded foundations.

Monolithic foundations are ideal for construction on unstable soils. This foundation is not terrible high groundwater level. Such foundations differ excellent endurance and ability to serve as the basis for cumbersome and heavy multi-storey buildings.

Prefabricated foundations consist of interconnected foundation slabs. Such a foundation is less stable, but for some buildings it is optimal, since the cost of such a foundation is slightly lower than that of a monolithic one. In addition, the construction of prefabricated foundation is much faster than monolithic.

Whichever type of foundation you choose, construction of the foundation should be trusted only by professionals. After all, the reliability of the foundation is the reliability of the entire building as a whole. Any mistakes in the construction of the foundation in the future can lead to disaster.

Industrial construction of high-speed warehouses

With the development of business, the need for specialized premises, such as warehouses, hangars and storage facilities, also increases. Thanks to modern technologies for the construction of prefabricated buildings, the construction of such premises does not take much time and is quite affordable.

Advantages of quickly erected warehouses:

1. High speed of erection of a building.

2. Low cost of building materials.

3. Simple installation of the frame and panels.

4. The possibility in the future to change the layout, reduce or increase the room without stopping production.

5. Reliability and security of the premises.

6. High stability of quickly erected warehouses for corrosion, external and internal negative factors.

Industrial construction of warehouses is handled by companies specializing in the construction of prefabricated buildings. In the IC “SOLID” work on each warehouse begins with communication with the customer, determining the purposes of construction. Formed the basic parameters and requirements for the future building. The customer chooses materials for construction. We work only with quality, certified building materials. This approach allows us to be confident in the quality and safety of the buildings we built.

After discussing all the parameters and wishes of the customer, our specialists leave for the construction site. Assess the condition of the soil. They form a list of preparatory works for construction.

In accordance with the draft of the building, materials are purchased. Installation takes place on the prepared land. Our employees strictly observe all technical norms and rules of installation and construction.

We pay special attention to the roof of the building and the roofing materials. Modern materials make it possible to create roofs of various architectures, while absolutely hermetic, without seams and joints, to cover them with roofing coverings.

We finish the work on the object only when all the works are completely finished and the premises can be put into operation. Our company provides a full range of services for the industrial construction of prefabricated warehouses.